Press

KURZ@IAA2023, 5. – 8.9.2023

HALL A2, Booth C32

Messe München

IAA Summit 2023: LEONHARD KURZ presents pioneering steering wheel with operable crystals from Swarovski

<p><strong>Fürth/Germany, August 30, 2023</strong>: The IAA Summit 2023 from September 5 to 8 is part of IAA MOBILITY, and is one of the most renowned international B2B events for the automotive industry. As a platform for groundbreaking technologies, concepts, and solutions for the mobility of the future, the IAA Summit brings together leading automobile manufacturers, suppliers, and technology companies.</p>

<p>LEONHARD KURZ is actively shaping these trends and will be presenting numerous highlights from the areas of Exterior Design, Interior Design, Visionary Design, and Sustainability at its stand. Using real exhibits coupled with multimedia presentations and interactive features, visitors to stand C32 in hall A2 can experience up close innovative components as well as lighting and operating concepts for the vehicles of tomorrow.</p>

<p>Due to ongoing trends such as electromobility and autonomous driving, the fusion of smart technology with elegant design is in increasing demand. Decorative surfaces give the interior its very own character and can be equipped with smart functions that only become apparent at second glance. KURZ recognized this development at an early stage and offers its customers well thought-out, holistic solutions that fully meet the new requirements. Under the term ‘Crystal Design Luxury,’ the thin-film specialist presented a Human-Machine Interface (HMI) panel for vehicle dashboards at CES 2022 at the start of the year, which was developed in cooperation with Swarovski Mobility. At the IAA Summit 2023, another result of the successful cooperation between the two experts will be presented, namely an innovative steering wheel design concept.</p>

<p> </p>

<h2>Crystal Steering Wheel: Merging design and functionality</h2>

<p>Just like the HMI panel, the futuristic steering wheel with integrated real crystals from Swarovski also attracts everyone’s attention. The backlit solid-cut crystals are manufactured in Austria and achieve an incomparable depth effect thanks to their precise cut. They can be color-coordinated with the interior of the vehicle and create breathtaking visual highlights. “With this concept, we clearly show that design and decoration don’t have to be limited to the usual suspects, i.e., to elements such as trims or dashboard surfaces. In combination with the Swarovski crystals, the steering wheel lends the interior an air of elegance and exclusivity. On the other hand, the futuristic design with light colors and transparent surfaces creates a whole new sense of lightness - a trend for vehicle interiors that will become even more popular in the coming years," emphasizes Jörg Stierand, LEONHARD KURZ Head of Divisional Sales Management Automotive, and adds: “Together with the invisible touch control and the option of equipping the steering wheel display with an antiviral and antibacterial surface, a well thought-out overall concept is created in which design and functionality merge.”</p>

<p>Six Swarovski crystals are integrated in the Crystal Steering Wheel - three each to the left and right next to the centrally mounted display. Thanks to ultra-thin, highly transparent sensor technology from KURZ subsidiary PolyIC, including backlighting, they only reveal their smart functionality when they are approached or touched by the user. Its surface is fully transparent, scratch-resistant, and easy to clean, despite the built-in sensors. “The steering wheel is another milestone in the successful cooperation between LEONHARD KURZ and Swarovski Mobility. After the successful introduction of crystal elements in the automotive luxury segment, we are looking at further possibilities to implement innovations together as we continue with our creative collaboration,” explains Peter Widmann, Senior Vice President & Managing Director Swarovski Mobility, and continues: “Our specially prepared crystals transform a previously purely functional element - the steering wheel - into a special highlight that enhances the vehicle interior with a touch of luxury.”</p>

<p> </p>

<h2>PolyTC<sup>®</sup>: Ultra-thin sensors from PolyIC</h2>

<p>Trouble-free touch operation is made possible by a special treatment of the Swarovski crystals that equips them with conductive properties using sensors from PolyIC. “The capacitive sensors are characterized by their high transparency. Although they consist of wafer-thin metal mesh silver structures, they are particularly sturdy and flexible to adapt to a wide range of component geometries,” explains KURZ’s Jörg Stierand, and adds: “In addition, they are ideally suited for implementing automotive trends - such as surfaces that only come to life when approached or touched.”</p>

<p>Interested parties can find more information about KURZ’s trade fair presentation and solutions on the <a href="http://iaa.kurz-automotive.com/">IAA Summit website</a>.</p>

<p> </p>

<h2>At a glance</h2>

<p>IAA Summit 2023 in Munich from September 5 to 8, 2023<br> LEONHARD KURZ Stiftung & Co. KG: Hall A2, Stand C32<br> Our trade fair presentation focuses on Exterior Design, Interior Design, Visionary Design, Sustainability</p>

Efficient processes, recyclable decorations, a reduced carbon footprint: KURZ presents sustainable innovations at the 2023 IAA Summit

<p><strong>Fürth/Germany, August 23, 2023:</strong> The IAA Summit 2023, from September 5 to 8, part of IAA MOBILITY 2023, is the leading international B2B platform for the automotive industry. Manufacturers, suppliers, and technology companies will be presenting pioneering technologies, concepts, and solutions for the mobility of future generations at Messe München. The challenges and opportunities of a sustainable future are becoming increasingly important. From drive technology to interior decoration, and from reducing harmful CO<sub>2</sub> emissions to creating a circular economy - the entire automotive industry is in a state of upheaval.</p>

<p>Under the motto ‘Be a green Leader,’ LEONHARD KURZ is actively shaping this change and playing a pioneering role in the field of surface finishing. “Efficient processes, durable decorations, and a demonstrably reduced carbon footprint are crucial topics for the entire industry. Together with designers, engineers, strong partners, and our subsidiaries, we are constantly working on optimal solutions along the entire process chain,” explains Rainer Süssmann, Executive Senior Vice President of the Business Area Plastic Decoration at LEONHARD KURZ. Many of these solutions can be experienced up close at the IAA Summit 2023 in hall A2 at stand C32.</p>

<p> </p>

<h2>Stunning designs and sustainable brand statements</h2>

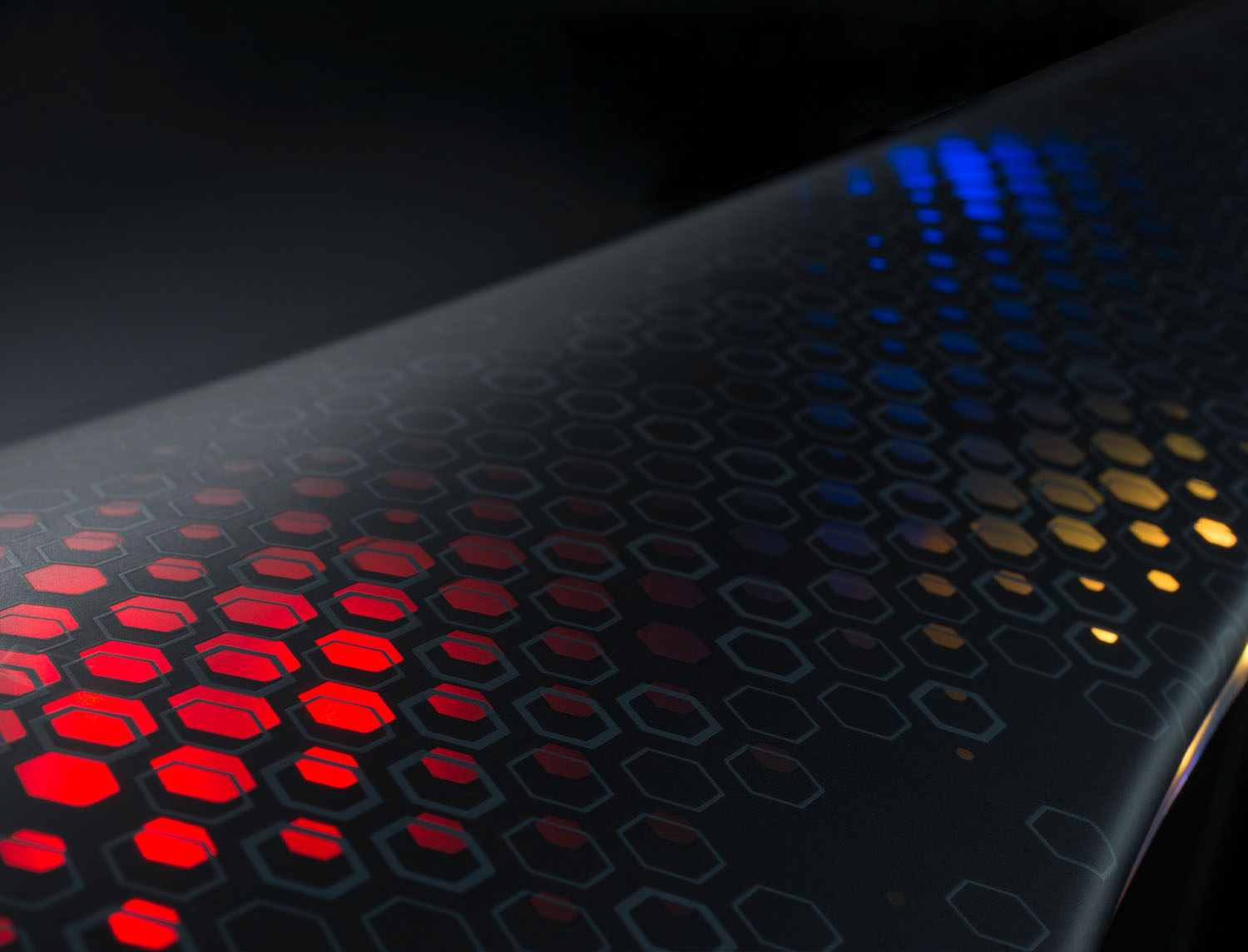

<p>Several sustainable highlights will be presented at the KURZ stand, including a futuristic-looking rear panel, which uses light signals to communicate with other road users and makes an unparalleled brand statement. The spectacular Rear End Cover is created in a single process step, in which all the necessary sensors can also be integrated at the same time. Production using the 2K IMD process reduces CO<sub>2</sub> emissions by combining several process steps into one single step. In addition, the component as a whole can be recycled. This also goes for the front grille panel presented by KURZ with a customizable and high-quality metallized surface that is 5G and radar capable. Here, production and decoration processes are also combined in a single highly efficient work step. This not only saves costs and time, but can also save up to 95 percent CO<sub>2</sub> compared to conventional processes such as electroplating.</p>

<p> </p>

<h2>From EV charging stations to hygiene protection</h2>

<p>Using an innovative wallbox that can be made from post-industrial recycled materials, KURZ impressively demonstrates that manufacturers don’t have to make any compromises in design and finishing compared to new material. Thanks to the flexible manufacturing process, the EV charging station can be adapted to any need, is fully recyclable, and can be made from up to 100 percent recycled material.</p>

<p>What does a recyclable decoration that is thinner than a human hair look like? KURZ provides the answer with artistically finished wheel rim inserts, which are predestined for electric vehicles, in particular due to their aerodynamic properties. In the spirit of sustainability, KURZ uses an advanced decoration process in which both the use of materials and energy consumption have been reduced compared to conventional technologies.</p>

<p>For surfaces that are touched frequently, KURZ offers long-term invisible hygiene protection with BIOFENSE<sup>®</sup> ANTIVIRAL, which can be combined with any design and almost any plastic surface. The antibacterial and antiviral coating is absolutely harmless to health and free of heavy metals. Surfaces can be decorated in just one step and equipped with BIOFENSE<sup>®</sup> ANTIVIRAL. This also saves energy and significantly reduces CO<sub>2</sub> emissions.</p>

<p> </p>

<h2>Visionary Design: New sustainable materials</h2>

<p>At the IAA Summit 2023, KURZ will be showcasing extraordinary experiments with new recycled materials that not only impress with their incomparable feel and look, but also accommodate smart functions such as backlighting and Shy Tech. Using these cutting-edge materials saves natural resources, is CO<sub>2</sub> efficient, and offers even more possibilities than nature itself. As part of the Spacewood Experiment project, for example, unique creations emerged that are made entirely from recycled materials and are themselves also fully recyclable. The Naturals project is very similar. Developed in conjunction with KURZ subsidiary BURG DESIGN, the designs draw inspiration from natural materials such as grass and wood and are more flexible to use than real materials. The ‘Naturals’ sample exhibits also consist entirely of recycled materials.</p>

<p> </p>

<h2>Sustainability advantages with KURZ</h2>

<p>Decorations from KURZ are currently made with 30 percent renewable raw materials, and this proportion is constantly increasing. Thanks to the well-founded expertise of the thin-film specialist in the development and implementation of environmentally friendly decorations, customers can significantly optimize their CO<sub>2</sub> balance. This is made possible, among other things, by efficient production processes such as in-mold decoration and EU-compliant metallization with indium instead of electroplating, which reduces the carbon footprint by up to 95 percent.</p>

<p>KURZ’s durable and high-grade finishings are already 100 percent recyclable today and therefore do not affect the recyclability of components. KURZ also delivers cost-effective, reliable machines. “With twelve production sites in Europe, Asia, and the USA, as well as a strong network of subsidiaries and partner companies, we accompany our customers’ projects from the initial idea to the finished solution and advise them competently throughout the entire process,” adds Rainer Süssmann. “Our goal is a circular economy. That is why we are constantly working on the further development of our own standards, on constantly improving the recyclability of our products, and on producing even more resource-efficiently than before.”</p>

<p>KURZ mainly uses renewable energies and works with recycled materials that can be refined to the same high standard as new material. Thanks to the commissioning of its own recycling plant, the thin-film specialist is the first and only manufacturer able to convert used PET carrier material from production in the graphics industry into a valuable raw material.</p>

<p>During the recycling process, the transfer carrier residues are converted into recycled PET, or rPET for short. The recovered material can be used to produce new PET carriers. In addition, rPET boasts a wide range of applications in the injection molding process, which is to be further expanded in the future.</p>

<p>Thanks to RECOSYS<sup>®</sup> 2.0, CO<sub>2</sub> savings of up to 40 percent are already being achieved today. Scope 3 emissions can also be cut by up to 90 percent, based on 1kg of transfer product. The system thus offers a significant competitive advantage that also benefits the environment.</p>

<p>Interested parties can find more information about KURZ’s trade fair presentation and sustainable solutions on the <a href="http://iaa.kurz-automotive.com/">IAA Summit website</a>.</p>

<p> </p>

<h2>At a glance</h2>

<p>IAA Summit 2023 in Munich from September 5 to 8, 2023<br> LEONHARD KURZ Stiftung & Co. KG: Hall A2, Stand C32<br> Our trade fair presentation focuses on Exterior Design, Interior Design, Visionary Design, Sustainability</p>